Ceramic Ball Bearing Kit Differential front Polaris ACE

447,60 € 447,60 €

incl. 20% VAT plus shipping costs

JAY PARTS CeramicSpeed Ceramic Ball Bearing Kit Differential Front POLARIS ACE 325 – 900

The balls in Ceramicspeed eXtreme ball bearings are harder and tougher than anything that comes into contact with them: dust, grit, metal shavings or tiny mineral fragments. Imagine a bearing in which all contaminants are ground into microscopic powder by the balls themselves – a bearing that is unlikely to fail. Proven to be four times smoother than steel balls, it reduces friction in the bearing.

- Ceramic balls proven to be 4 times smoother than a steel ball

- Ceramic balls reduce friction in the bearing

- more power

- Longer service life in contaminated environments

- Made in Europe

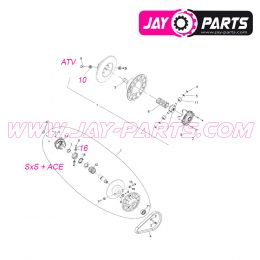

The JAY PARTS bearing kit for the Polaris ACE front differential includes 3 Xtreme ceramic ball bearings from premium manufacturer CeramicSpeed

ASSEMBLY NOTE

OIL: 180 – 200 ml Polaris Demand Drive Fluid it depends on the gearbox version

SCOPE OF DELIFERY

1 Bearing for the Pinion

2 Bearings at the Hub (Axle)

Replaces OEM 3235174

WORKS WITH THE FOLLOWING MODELS

Polaris ACE 325 – 900

Availability : in stock

These CeramicSpeed Ball Bearings are Bearings like No Other!

The CeramicSpeed Balls used in all CeramicSpeed bearings are proven to be 4 times smoother than a steel ball, which puts them into a league of their own when it comes to reduced friction in the bearing. And a bearing that is exposed to less friction will have an increased lifetime. Within the go-kart and motocross disciplines that use ball bearings in the engines, this can mean remarkably less engine bearing replacements and service.

More power and longer service life!

CeramicSpeed ball bearings - one of Jay's Secrets.

Within Motocross, there are numerous effects of a CeramicSpeed Bearing upgrade. Increased power and engine service life are among the most obvious benefits.

With a CeramicSpeed Ball Bearing in a Motocross engine, you will benefit from increased stiffness. Additionally, the lower rotating weight will lead to faster acceleration and the low friction caused by premium quality ceramic bearings will increase the lifetime of the engine bearings, and thus the service life.

CeramicSpeed Bearings are built with ceramic balls. Whilst ceramic might give the impression of fragile porcelain – this is a different ball game. These balls are made of the highest quality Grade 3 Silicon Nitride, featuring the highest achievable surface finish and roundness. CeramicSpeed Balls feature unparalleled impact strength, smoothness and roundness – which determines the performance and lifetime of a bearing.

In motorsport disciplines, the quality of the balls is crucial for the bearing’s ability to resist impact when placed in the wheel hubs or cause fast accelerations when placed in an engine.

Due to the surface of the balls and their ability to resist impact, CeramicSpeed Balls – and therefore CeramicSpeed Bearings – perform better than the rest. After 600 hours of testing, a CeramicSpeed Ball is in perfect condition, compared to other ceramic balls where the surface is rough and rugged after only 10 hours. Consequently, a ball with a rough surface creates increased friction and wears the races of the bearing down quickly.

CeramicSpeed Balls vs. Steel Balls

This picture shows two ¼" (6.35 mm) balls. The one to the left is a CeramicSpeed Ball and the one to the right is a standard steel ball. We applied the same pressure to both balls and the result is clear; the steel ball simply cracked under the load, while the CeramicSpeed Ball is 100% intact and perfectly usable.

Pic credit: Ceramicspeed

QUESTIONS & ANSWERS

Can CeramicSpeed Bearings run in contaminated environments?

The CeramicSpeed Xtreme series is designed for applications in contaminated environments, where particles can penetrate the bearing and affect the bearing performance. Characterized by unmatched harness, the hybrid balls tolerate a high degree of contamination, crushing the particles that penetrate into the bearing races. The Xtreme series are also highly resistant agaist water and detergents because Silicon Nitride does not corrode.

Can CeramicSpeed Bearings operate at extremely high speed?

CeramicSpeed bearings can operate at much higher RPMs – up to 50% higher – giving you the possibility of using long-life bearings in demanding high-speed applications, such as machine tool spindles and turbomachinery.

Add a review

Produktanfrage / Request to product: Ceramic Ball Bearing Kit Differential front Polaris ACE

Info

Manufacturer information

MANUFACTURER

CeramicSpeed MotorSport

Noergaardsvej 3, 7500 Holstebro, Denmark

+45 97 40 25 44

DISTRIBUTOR

JAY PARTS GmbH

Lothringen Strasse 6/20, 4501 Neuhofen an der Krems, AUSTRIA

info[at]jay-parts.com

Reviews

There are no reviews yet.